Steel Casting Parts with Complex Shape: An Exploration of Manufacturing Techniques

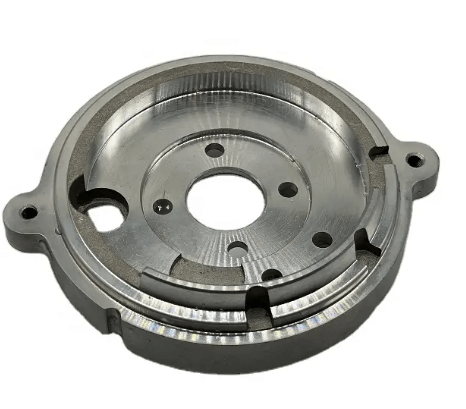

Steel casting is a widely used manufacturing process for producing complex-shaped parts. This article aims to delve into the various techniques employed in the production of steel casting parts with intricate geometries. It will discuss the significance of complex shapes, the challenges faced during manufacturing, and the innovative solutions employed to overcome these hurdles. By understanding the techniques involved in creating such parts, manufacturers can enhance their capabilities, improve product quality, and explore new possibilities in the realm of steel casting.

Section 1: Importance of Complex Shapes in Steel Casting:

Complex-shaped steel casting parts find applications in a multitude of industries such as automotive, aerospace, energy, and more. These intricate geometries allow for improved performance, increased efficiency, and enhanced functionality. For example, in the automotive sector, complex-shaped parts can contribute to weight reduction, fuel efficiency, and improved safety. In the aerospace industry, intricate castings are crucial for manufacturing turbine blades, engine components, and structural elements that require high strength and precision. Furthermore, complex-shaped steel castings often provide cost-effective solutions by eliminating the need for multiple assembled parts.

Section 2: Challenges in Manufacturing Complex-Shaped Steel Castings:

The manufacturing of steel casting parts with complex shapes presents several challenges. The intricate designs can lead to issues such as porosity, non-uniform cooling, and mold filling problems. Moreover, the intricate shapes may have thin sections or undercuts that make it challenging to extract the pattern from the mold. Additionally, the presence of internal cores and passages necessitates intricate mold design and careful consideration of metal flow.

Section 3: Techniques for Manufacturing Complex-Shaped Steel Castings:

3.1 Mold Design and Preparation: Creating a well-designed mold is crucial for manufacturing complex-shaped steel castings. Advanced computer-aided design (CAD) and simulation tools enable engineers to optimize the mold geometry, gating systems, and runner configurations. These tools aid in predicting the filling and solidification behavior, optimizing the mold layout, and minimizing defects.

3.2 Wax Pattern Production: The creation of a high-quality wax pattern is vital for achieving accurate and intricate shapes in steel casting. Rapid prototyping techniques, such as 3D printing, can be employed to generate wax patterns directly from CAD models, reducing lead times and allowing for design iterations. Injection molding and ceramic molding techniques are also used for producing wax patterns.

3.3 Ceramic Shell Formation: In the investment casting process, a ceramic shell is formed around the wax pattern. Multiple layers of ceramic slurry and refractory material are applied to create a strong and heat-resistant mold. Advanced techniques like the use of zircon or alumina-based slurries, dipping and slurry rotation, and stucco coating can improve the mold’s quality, dimensional accuracy, and surface finish.

3.4 Shell Dewaxing and Preheating: Once the ceramic shell is formed, the wax is removed through a process called dewaxing. It can be achieved through various methods like steam autoclaving, thermal cracking, or flash firing. Preheating the shell after dewaxing helps eliminate residual moisture and prevents shell cracking during metal pouring.

3.5 Metal Pouring and Solidification: During metal pouring, the preheated ceramic shell is filled with molten steel. Controlled pouring techniques, such as vacuum-assisted casting or centrifugal casting, ensure proper filling and reduce the risk of defects. Solidification time and cooling rates are carefully managed to prevent thermal stresses and ensure the desired metallurgical properties.

Section 4: Innovations and Future Directions:

The integration of artificial intelligence (AI) and machine learning (ML) algorithms in steel casting processes shows promising potential. AI can be utilized to optimize mold design, predict defect formation, and improve process control. ML algorithms can analyze vast amounts of data from past casting operations to identify patterns, optimize parameters, and enhance quality control.

Furthermore, additive manufacturing, commonly known as 3D printing, is being explored as a complementary technique to traditional steel casting. By combining casting with 3D printing, manufacturers can create complex-shaped patterns and molds with intricate internal geometries that were previously difficult or impossible to achieve. This hybrid approach allows for greater design freedom, reduced lead times, and improved efficiency.

The use of advanced materials, such as high-strength alloys and metal matrix composites, is another area of focus in the manufacturing of complex-shaped steel castings. These materials offer superior mechanical properties, enhanced heat resistance, and improved wear characteristics, making them ideal for demanding applications in industries such as aerospace, defense, and energy.

Conclusion:

Steel casting parts with complex shapes play a vital role in various industries, offering enhanced performance, improved efficiency, and cost-effective solutions. Although manufacturing such parts presents challenges, innovative techniques and technologies are continually being developed to overcome these hurdles. Mold design optimization, advanced wax pattern production, ceramic shell formation, and precise metal pouring and solidification techniques are crucial for achieving accurate and intricate shapes. Furthermore, the integration of AI, ML, additive manufacturing, and advanced materials opens up new possibilities for the production of complex-shaped steel casting parts. By staying at the forefront of these developments, manufacturers can elevate their capabilities and meet the evolving demands of the market.

Applications of Steel Casting Parts with Complex Shape

Metal casting has a wide range of applications across various industries. Here are some of the most common industries that use metal casting:

Automobile and Aerospace Industry

The automobile and aerospace industries are two of the biggest users of metal casting. Metal casting is used to create various parts of a car or an aircraft. Some of the parts include engine blocks, transmission cases, and wheels. The reason why metal casting is preferred in these industries is that it allows for the creation of complex shapes and designs that cannot be achieved by other manufacturing processes.

Jewelry Making

Metal casting is also used in the jewelry making industry. It is used to create intricate designs and shapes that are not possible with other manufacturing processes. Jewelry makers can use metal casting to create rings, bracelets, necklaces, and other accessories. The most commonly used metals for jewelry making are gold, silver, and platinum.

Sculptures and Weapons

Metal casting is also used in the creation of sculptures and weapons. Sculptors can use metal casting to create intricate designs and shapes that cannot be achieved with other manufacturing processes. Weapons manufacturers can use metal casting to create swords, knives, and other weapons. The most commonly used metals for sculptures and weapons are bronze and iron.

Shipping and Manufacturing

Metal casting is also used in the shipping and manufacturing industries. It is used to create various parts of a ship, such as propellers and rudders. It is also used to create various parts of manufacturing equipment, such as gears and pulleys. The most commonly used metals for shipping and manufacturing are steel and iron.

Metal Casting Books and Resources

Metal casting is a complex process that requires knowledge and expertise. Fortunately, there are many books and resources available to help those interested in learning about the subject. This section will cover two types of resources: metal casting books and metal casting suppliers.

Metal Casting Books

There are many books available on metal casting, covering a wide range of topics from the basics of casting to advanced techniques. Some of the most popular books on metal casting include:

- Complete Casting Handbook by John Campbell

- Metal Casting: Appropriate Technology in the Small Foundry by Steve Chastain

- Foundrywork for the Amateur by Percy Blandford

- The Art of Casting: A Complete Introduction to Foundry Practices and Procedures by Richard Gingery

These books provide a wealth of information on metal casting, from the basics of the process to advanced techniques. They are a great resource for anyone interested in learning more about metal casting.

Metal Casting Suppliers

In addition to books, there are many suppliers that sell equipment and materials for metal casting. Some of the most popular suppliers include:

| Supplier | Website | Stock |

|---|---|---|

| Budget Casting Supply | https://budgetcastingsupply.com/ | Yes |

| Centaur Forge | https://www.centaurforge.com/ | No |

| McMaster-Carr | https://www.mcmaster.com/ | Yes |

| Reliable Bronze & Manufacturing | https://www.reliablebronze.com/ | No |

These suppliers offer a variety of equipment and materials for metal casting, including furnaces, crucibles, sand, and molds. They are a great resource for anyone looking to get started with metal casting or to expand their capabilities.